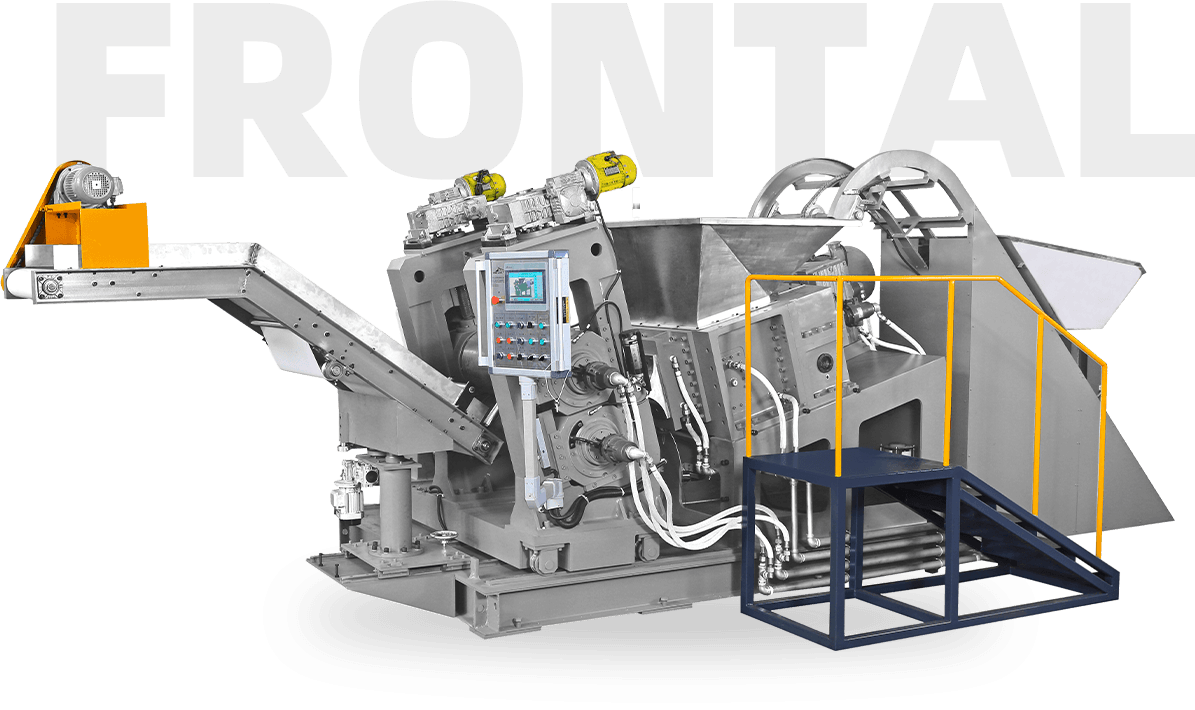

5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenanceand long machine life.

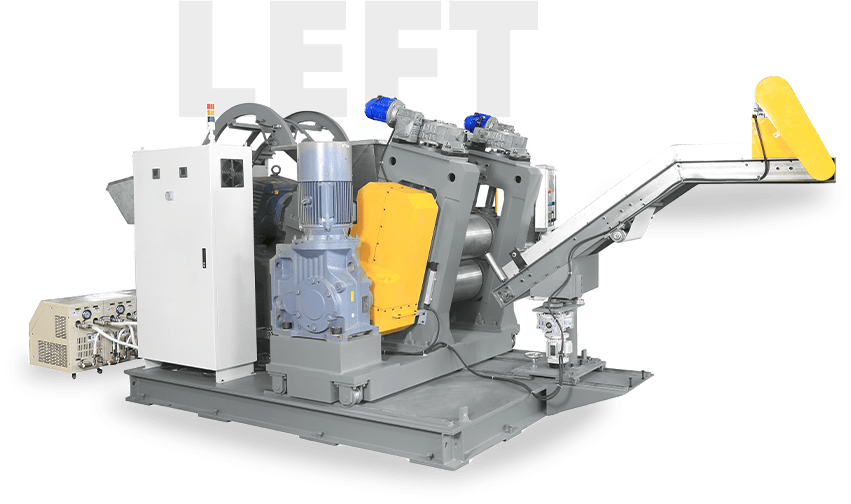

2. lt can be produced continuously and automatically, which is the best equipment for automation

3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubbermaterials after mixing into it without material accumulation and residual material

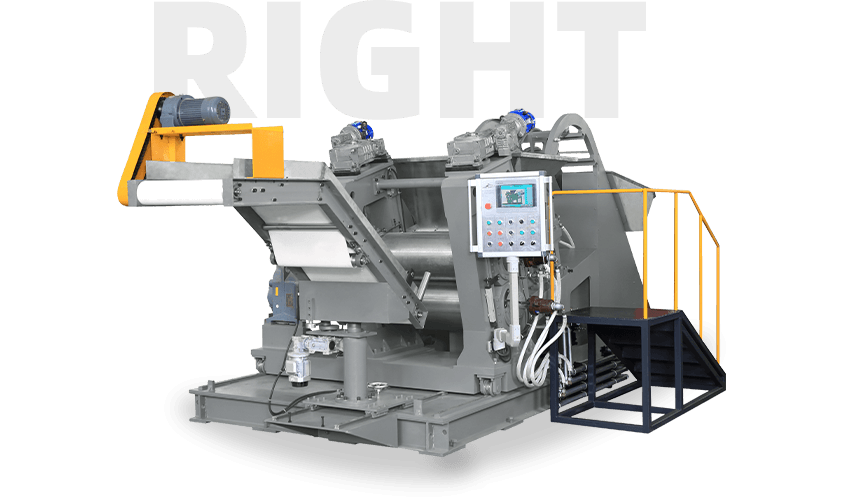

Comparison

physical properties and sheet quality.

continuous production, reducing overall line efficiency.

machine lifespan.

physical properties of rubber sheets.

rubber continuously without stops.

handling, leading to high labor intensity and

inconsistent sheet thickness.

labor intensity and inconsistent sheet thickness?

2.Intermittent production with frequent stops for material transfer and cooling?

3.Residual rubber remains in the chamber, causing waste and increasing costs?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

as a mixer’s auxiliary machine to continuously extrude refined

rubber into specified sheets, replacing a calender for wide film

production, enabling automated processing to boost efficiency

and reduce labor.