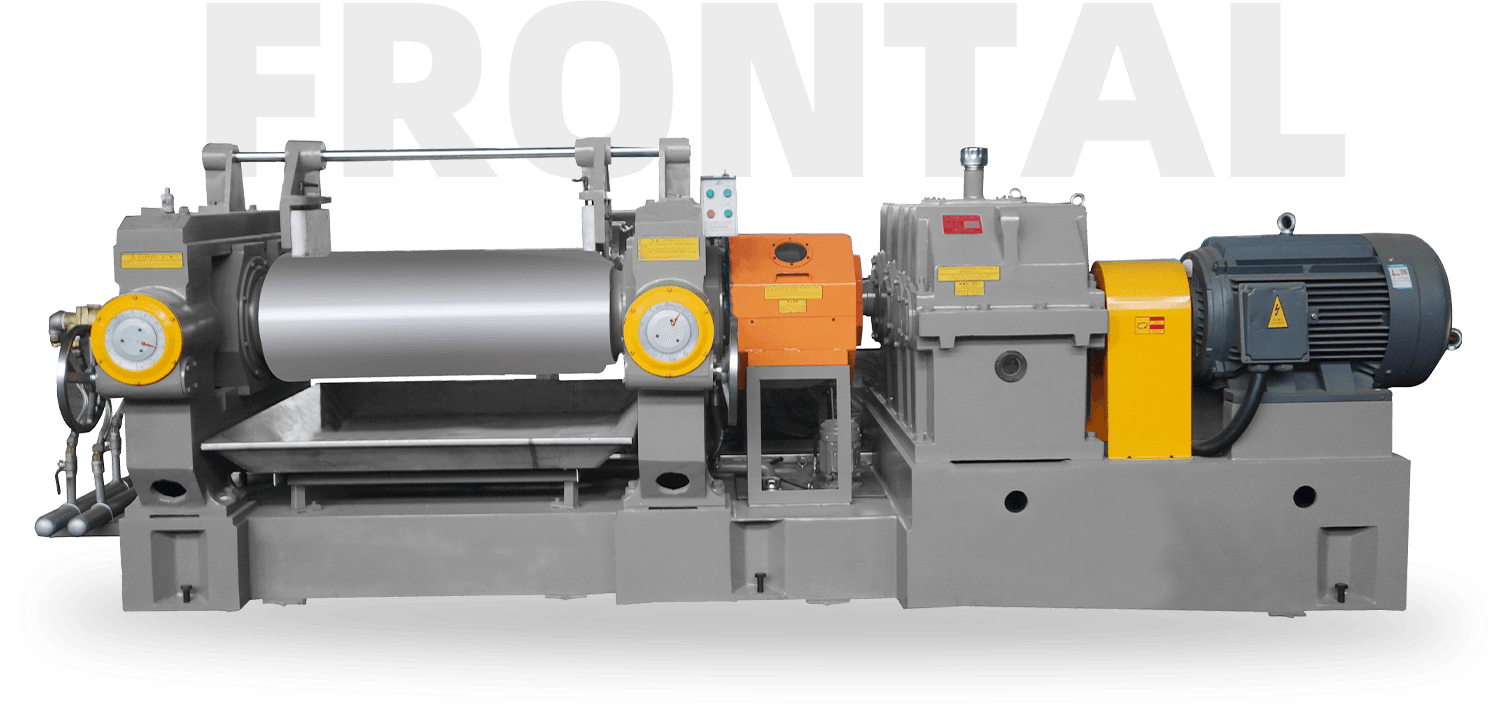

3, The roller adopts self-aligning bearing, low energy consumption, convenient maintenance, long servicelife;

5. The lubrication system adopts integrated circulation lubrication to reduce oil leakage.

Comparison

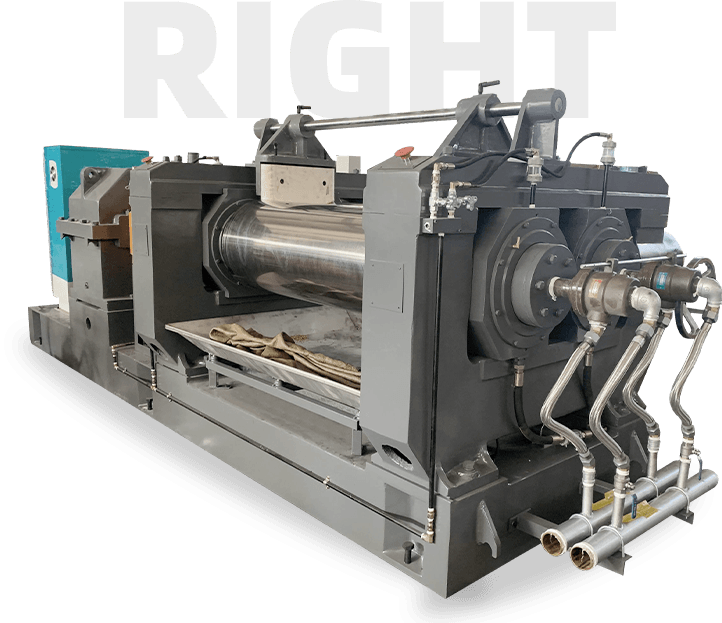

accumulation and ensures full utilization of rubber.

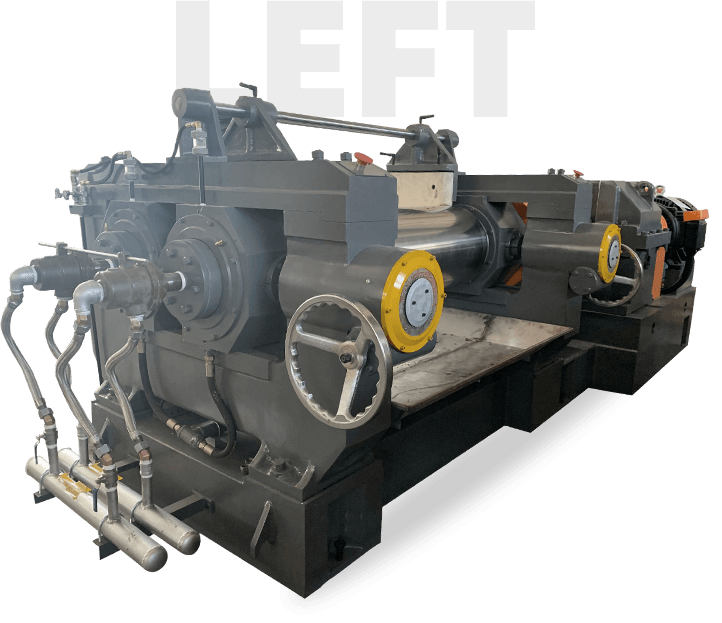

resulting in waste and cleaning downtime.

sheet thickness and stable physical properties.

cause variations in sheet thickness and properties.

enhances safety and reduces operator exposure.

increase accident risks during emergency stops.

costs and operator fatigue?

2.Operates intermittently, causing frequent stops and lower production efficiency?

3.Residual rubber often sticks to rollers, resulting in waste and cleaning downtime.?

Discover the power of smart lasting automation—stable, efficient, and easy to use.