Comparison

, deformation, or blistering of heat-sensitive materials

shrinkage, deformation, or blistering

consumption focused on curing

2.Heat-sensitive materials prone to damage?

3. Complex maintenance, operation depends on experience?

4.Lower efficiency, high energy consumption?

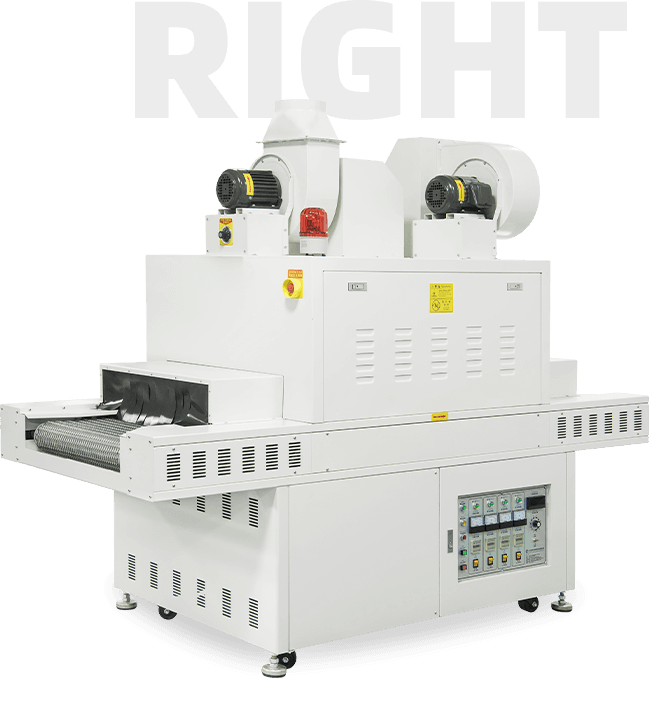

Discover the power of smart lasting automation—stable, efficient, and easy to use.

and EVA and MD shoe materials. It can also be applied to other

fields that require UV curing, such as material curing and surface

treatment in printing, packaging, electronics and other industries.