Characteristics Comparison

Some advantages of our machines compared with other manufacturers

Still struggling with traditional lasting machines?

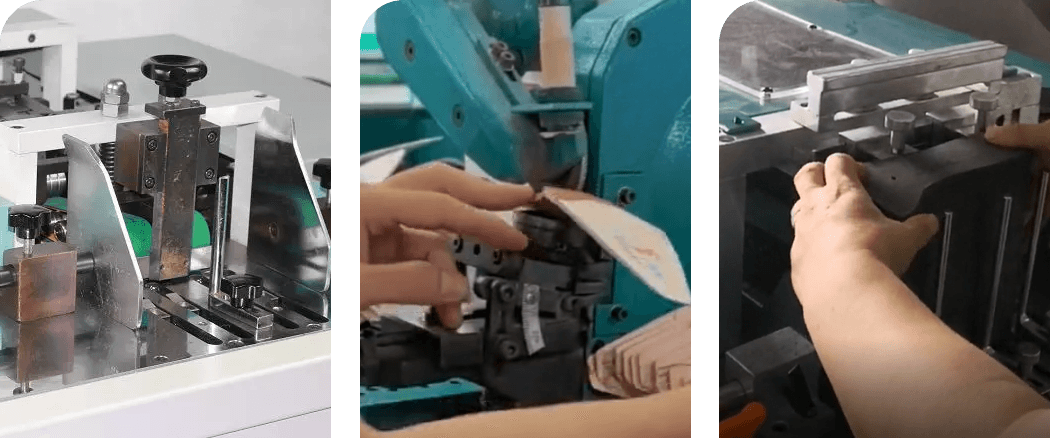

1.Skived surface is rough, requiring extra polishing before bonding?

2.Output is low and multiple operators are needed?

3.Different thicknesses require changing molds?

4.Traditional machines are noisy and consume more power?

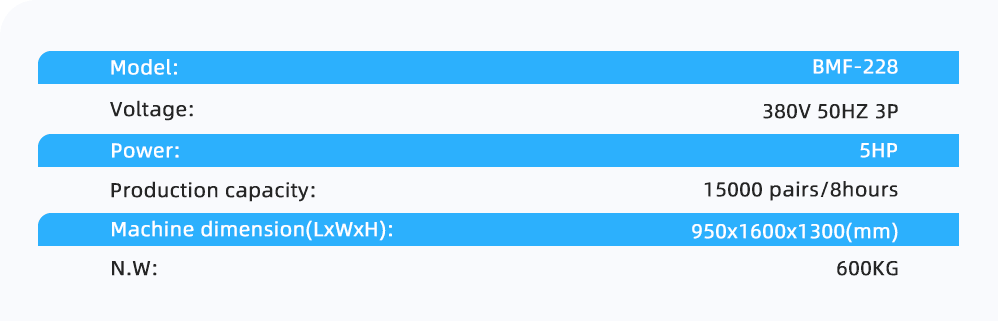

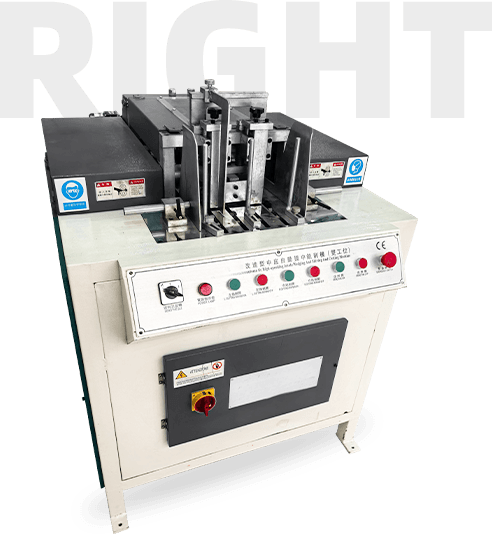

Parameters

Skiving machine for insoles —- BMF-228