Characteristics Comparison

Some advantages of our machines compared with other manufacturers

Still struggling with traditional lasting machines?

1.Manual operation often causes excessive glue use, resulting in waste and unstable coating thickness?

2.Open containers lead to glue evaporation, strong odors, and VOC emissions, affecting worker health and air quality?

3.Glue is exposed to air, easily thickens or dries out, reducing bonding strength and causing defective products.?

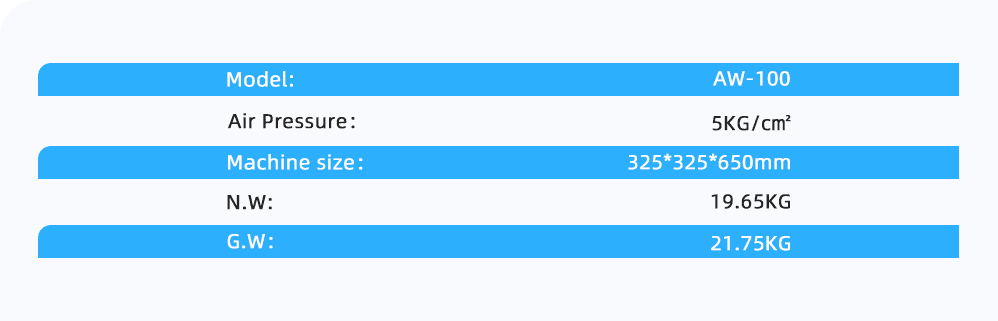

Parameters

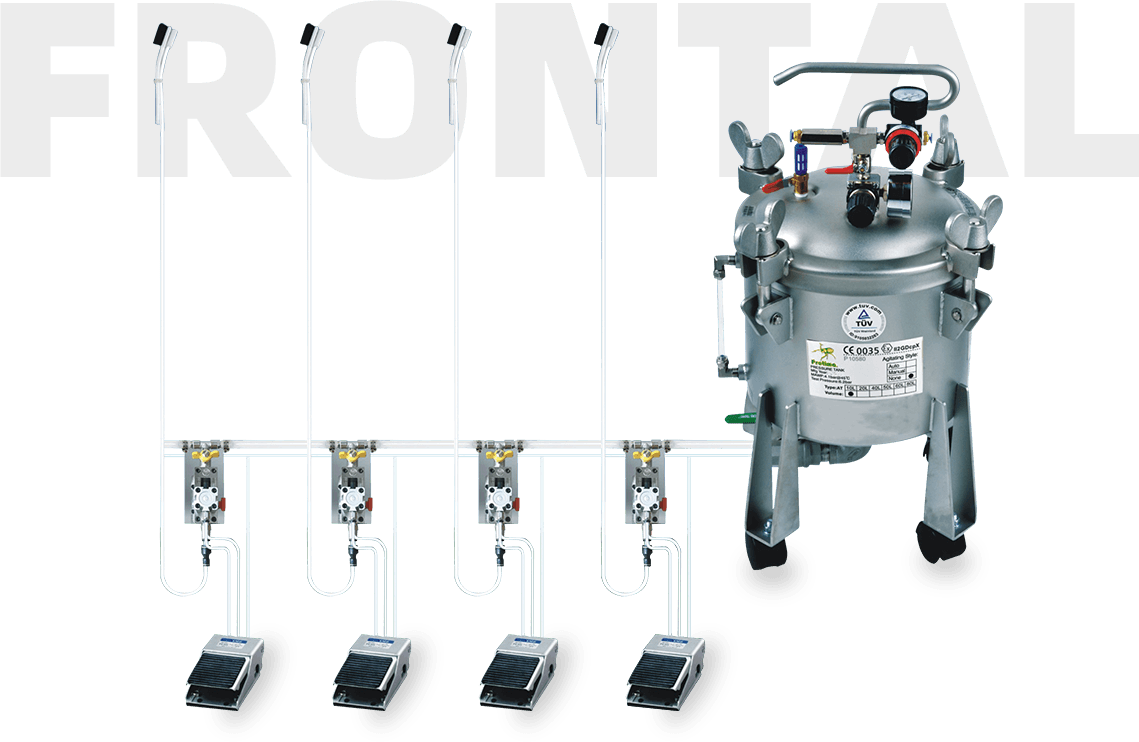

Water-based/Oil-based Dual-purpose Glue Brushing Machine—-AW-100