what we do…

EVA FOAMING LINE MACHINERY

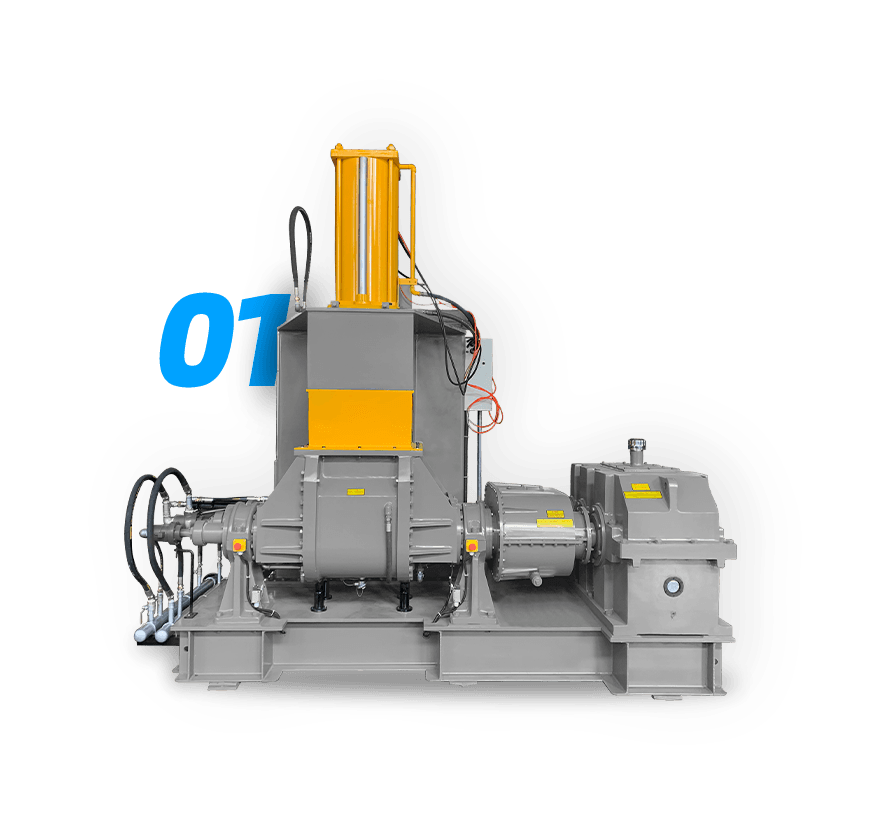

KNEADER MIXER

1.Adopts oval shearing rotor, all working faces of rotor, mixing chamber surface and upper bolt are surfacing with wear-resistant hard alloy, the service life is 3 to 10 times of the general mixer

2. Automatic temperature control system, precise and convenient operation, mixing up to the best dispersing effect and evenness.

3. The transmission uses hardened gear reducer, compact structure, transmission efficiency, low noise, long service life.

4. Pneumatic control system uses Japan’s SMC, Fuji Omron and other world-class brands.

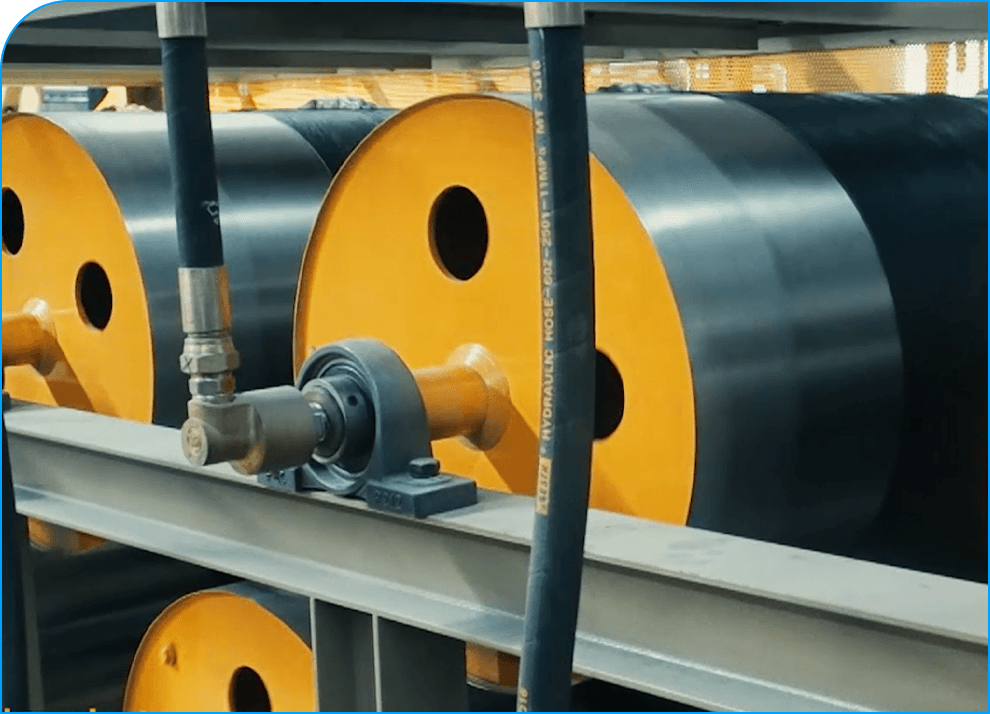

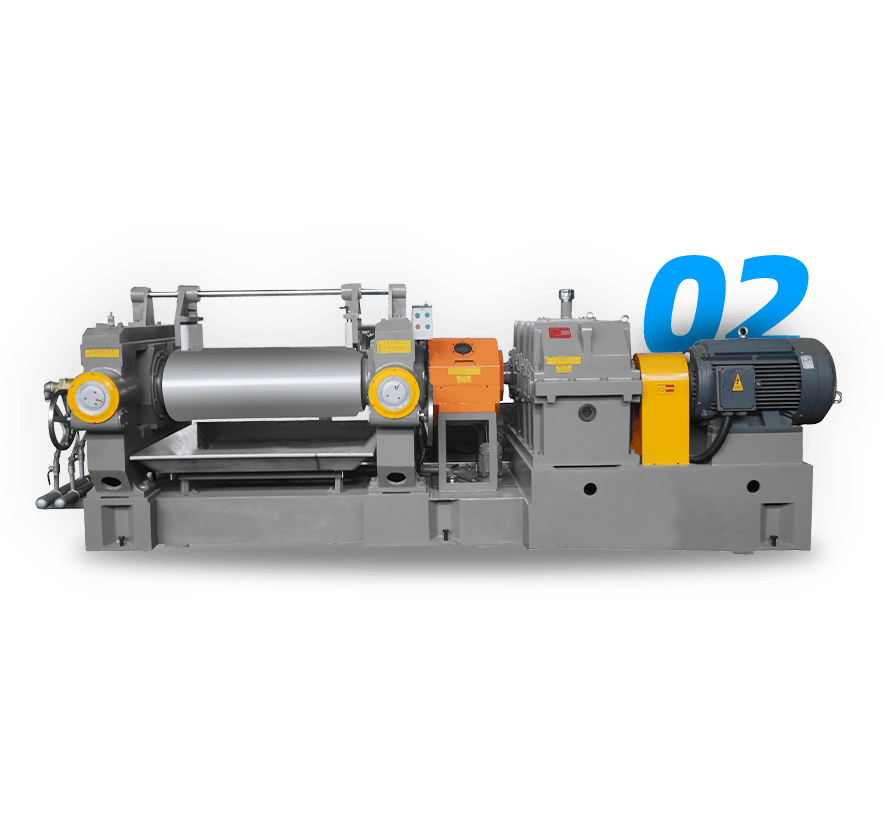

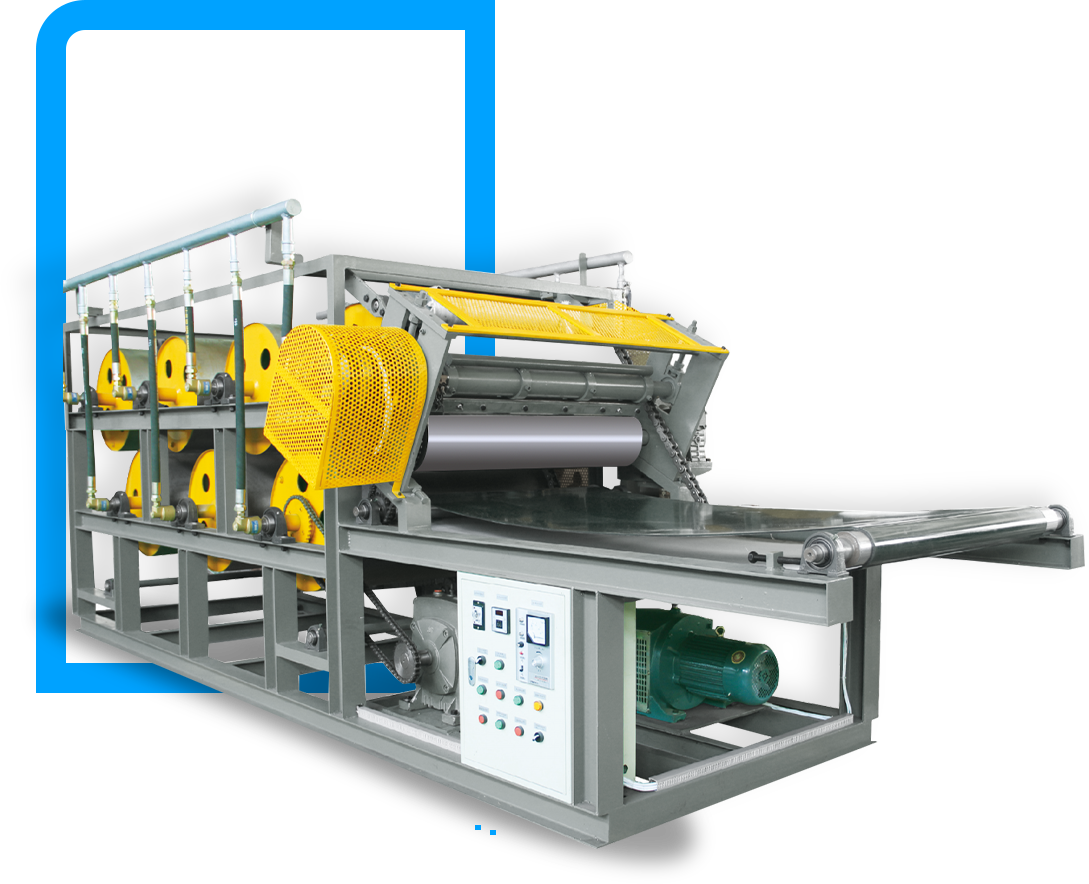

Open Mixing Mill

1. The roller material is vanadium-titanium alloy chilled cast iron and the roller structure is heated or cooled by drilling or hollowing to make the roller surface temperature uniform;

2. Hard surface reducer for transmission system, compact structure, low noise and high efficiency;

3. The roller adopts self-aligning bearing, low energy consumption, convenient maintenance, long service life;

4.The machine is equipped with hydraulic and electric power reverse braking device.

5. The lubrication system adopts integrated circulation lubrication to reduce oil leakage.

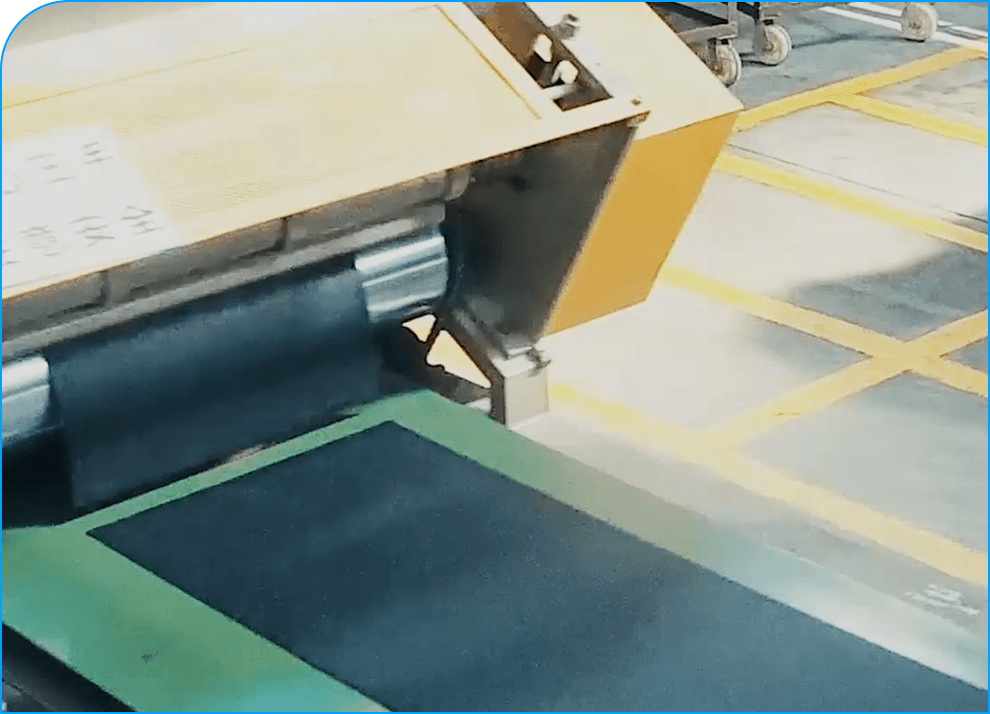

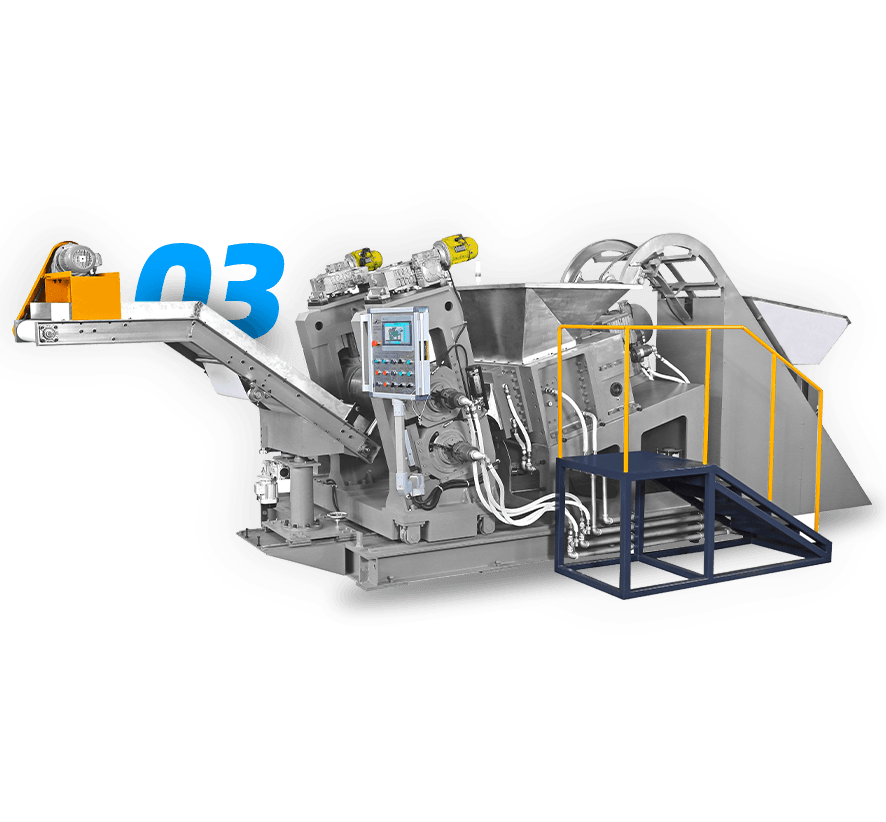

Double Taper Sheet Extruder

1. Save manpower and energy.

2. It can be produced continuously and automatically.

3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubber materials after mixing into it without material accumulation and residual material.

4. Good cooling efficiency, high cooling efficiency of the rubber compound.

5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenance and long machine life.

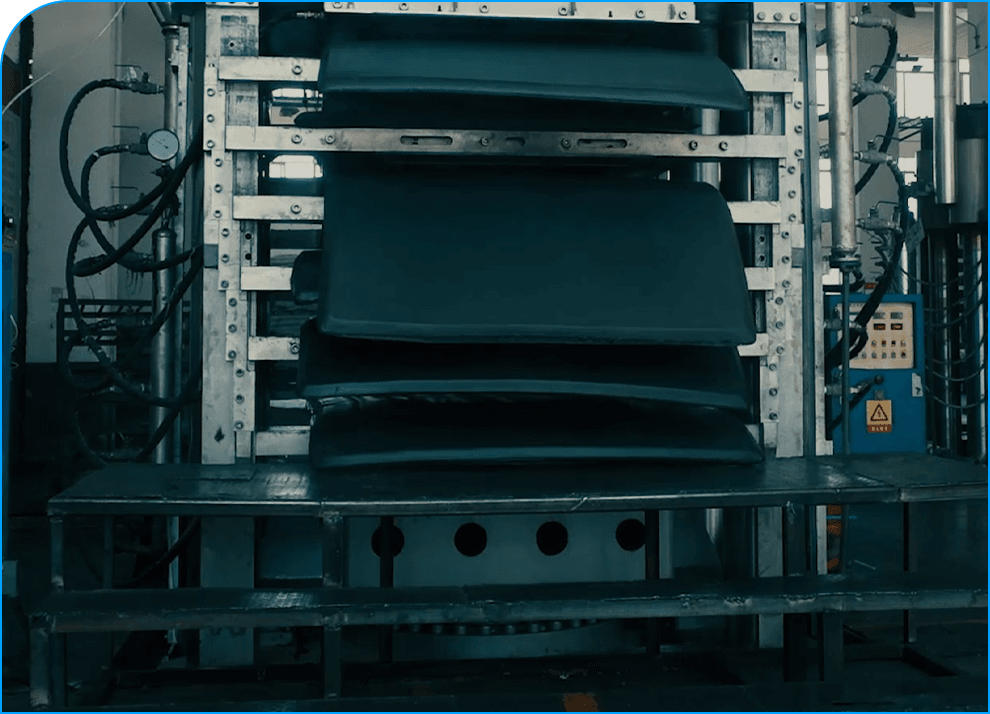

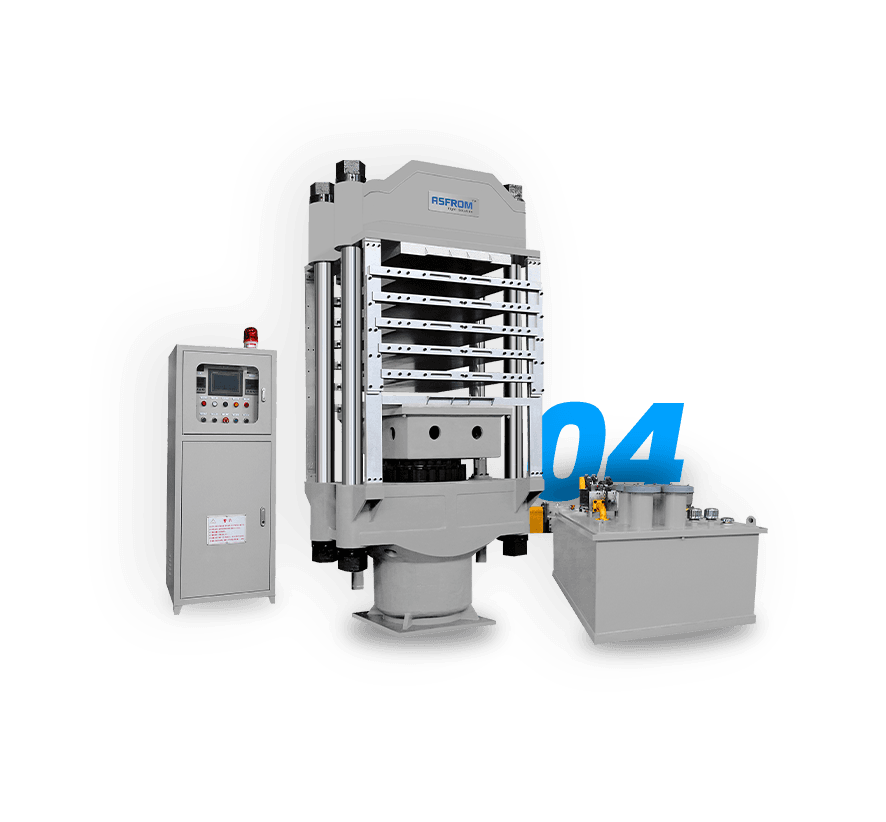

Hydraulic Press Machine

1. Automatic ascending, bumping, pressurization and descending operations.

2. High speed ascending, pressure retaining for better product quality.

3. Quick release valve for quick descending but incorporates adjustable speed.

4. Depressurization can be adjusted according to products thickness.

5. Special designed platens for even heating area.

6. The above features can be incorporated in, automatic and semi-automatic machines.

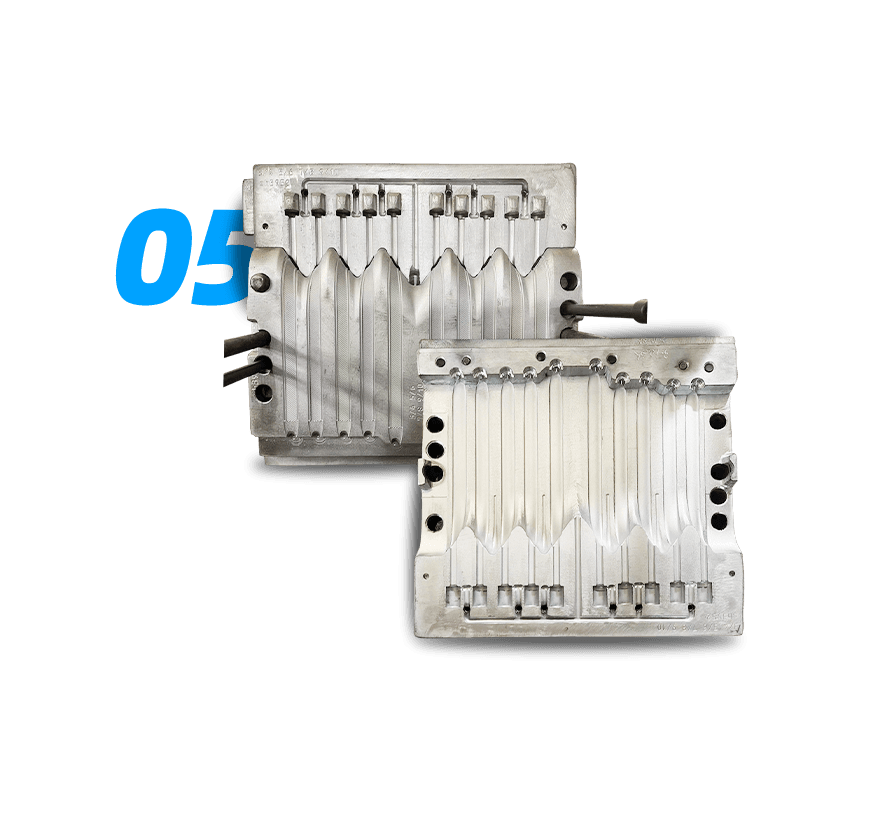

EVA Mold

1. Automatic ascending, bumping, pressurization and descending operations.

2. High speed ascending, pressure retaining for better product quality.

3. Quick release valve for quick descending but incorporates adjustable speed.

4. Depressurization can be adjusted according to products thickness.

5. Special designed platens for even heating area.

6. The above features can be incorporated in, automatic and semi-automatic machines.

Expertise

Why You Should Choose US

As a shoe machinery manufacturer, we assist customers by first ensuring clear communication and gathering detailed information about the issue. We offer troubleshooting advice and remote support for common problems. If needed, we arrange on-site service and send necessary spare parts. After resolving the issue, we follow up to ensure the machine is working properly and provide recommendations for maintenance and training.