Characteristics Comparison

Some advantages of our machines compared with other manufacturers

Still struggling with traditional lasting machines?

1.Manual fatigue leads to inconsistent results and high scrap rate?

2.Slow and inefficient, difficult to meet fast production demands?

3.Cannot handle mixed material thickness like XPE + leather layers?

4.Imprecise cutting, unsuitable for high-tolerance parts?

5.Dust & noise generation from traditional rotary blades?

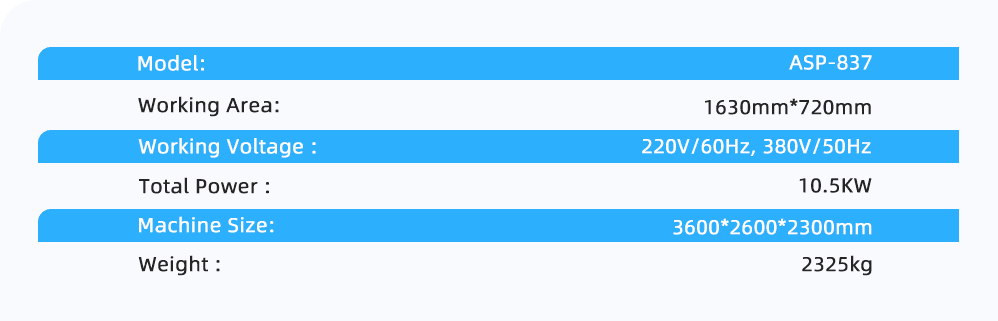

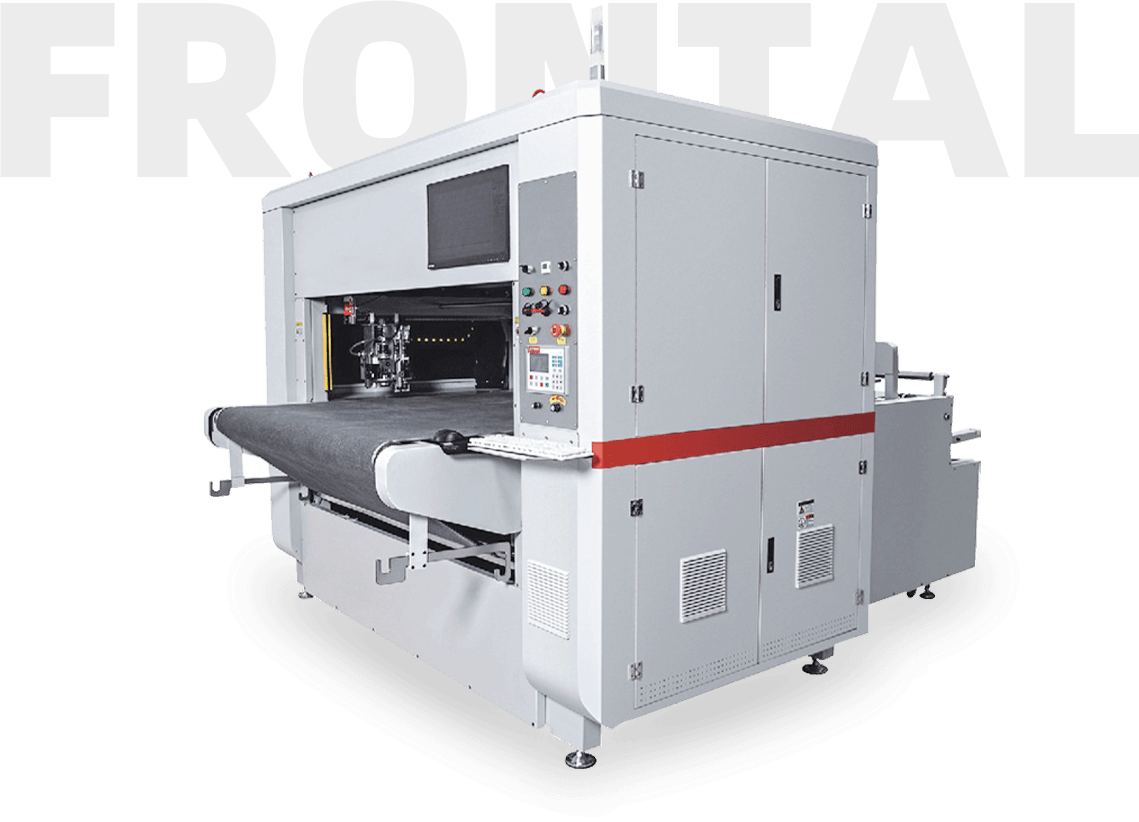

Parameters

Vibrating Knife Cutting Machine—ASP-837