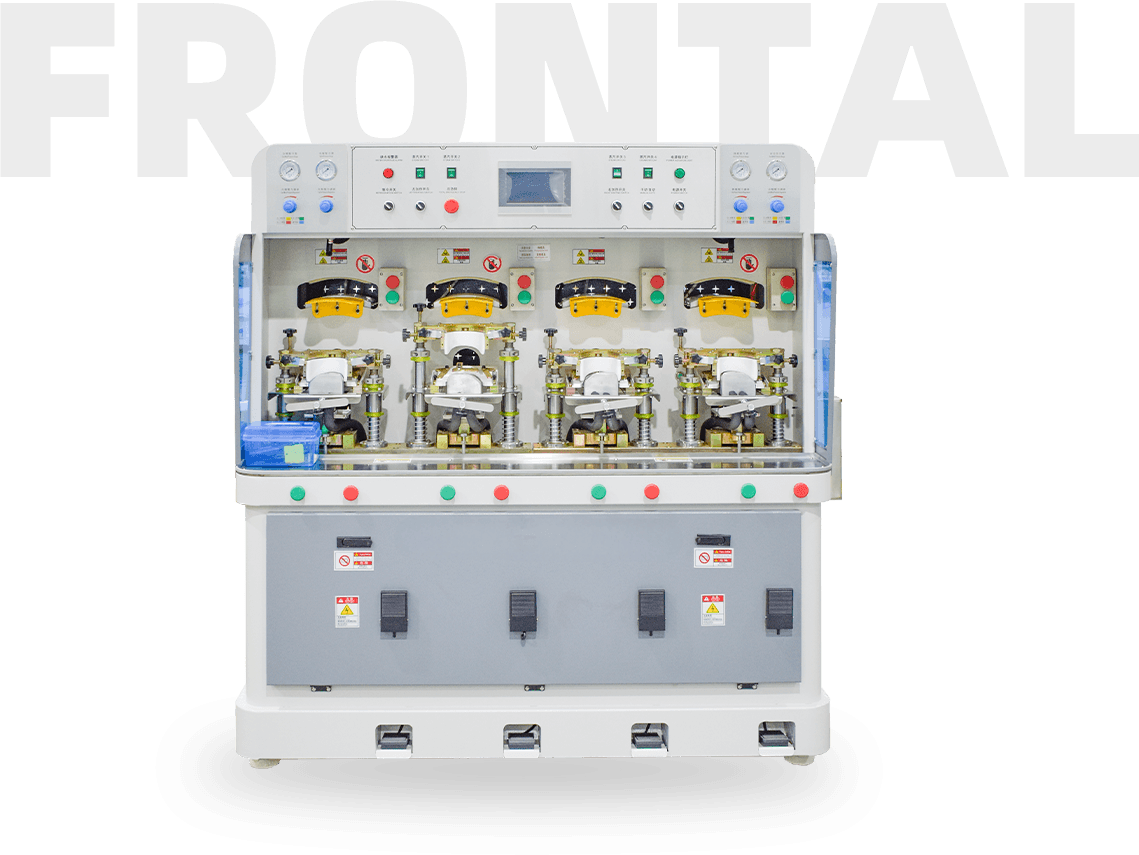

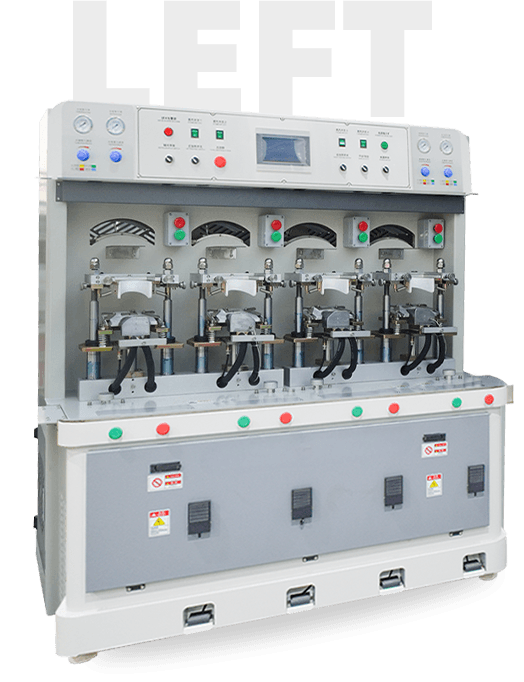

In order to solve the problems of wrinkling and distorted toe cap that are prone to occur in the traditional shoe lasting process, this machine uses an intelligent temperature control and pressure adjustment system to achieve three-dimensional shaping of the toe cap. The precise hot and cold pressing alternating process can effectively eliminate the internal stress of the material, ensure that the shoe surface is flat and smooth, and significantly improve the aesthetics of the finished product.

The unique one-step shaping process eliminates the locking and reinforcement steps in traditional processes, and the toe shaping and shaping can be completed in a single operation. According to tests, the shaping time of a single pair of shoes is shortened by 30%, and there is no need for secondary hammering and correction, the labor cost is reduced by 20%, and the production capacity is significantly improved.

Molding Machine

Molding Machine ---

Comparison

achieves 3D shaping; hot & cold alternating

pressing eliminates stress, ensures smooth

surface, and improves aesthetics.

surface flatness hard to control.

independently adjustable; stable, uniform

shaping with flexible parameter control.

leads to unstable shaping.

operations; shaping cycle shortened, production

capacity significantly improved.

lower output.

2.Complicated to adjust; new workers find it difficult, requires long training?

3.Higher failure rate, frequent downtime, increased repair costs?

4.Single-zone heating wastes energy, low utilization efficiency?

5.Limited flexibility, hard to meet diverse shoe styles and quality standards?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

various men's, women's and children's shoes. It can also be

used for shaping the toe caps of hot melt adhesive welted shoes,

mark shoes and work shoes.