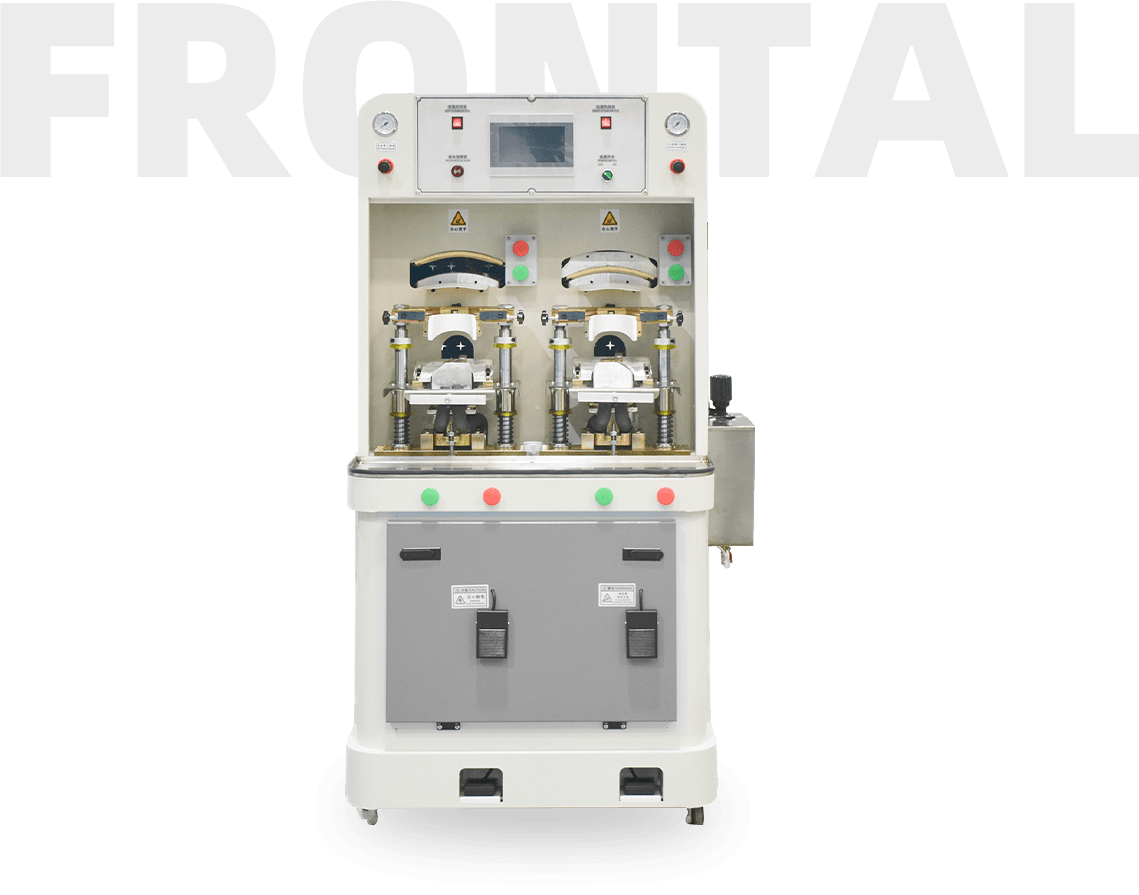

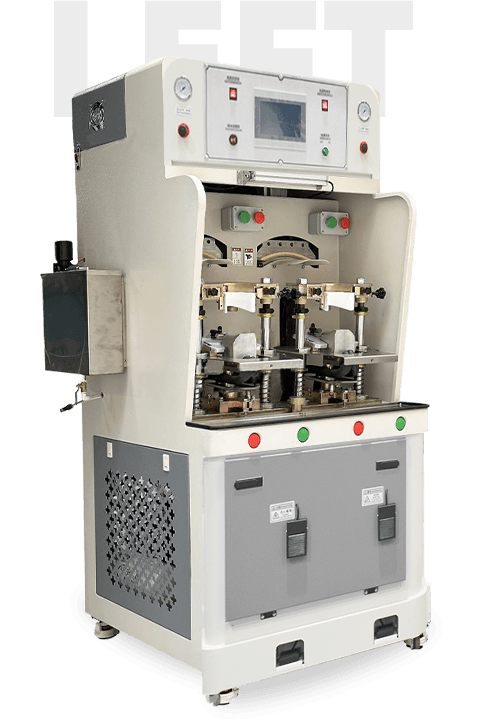

The innovative upper and lower hot and cold pressing design reduces the floor space by 40% compared with the traditional left and right structure models. The modular design supports fast mold change and adapts to different shoe last sizes, which is particularly suitable for manufacturers with limited space to achieve efficient and intensive production.

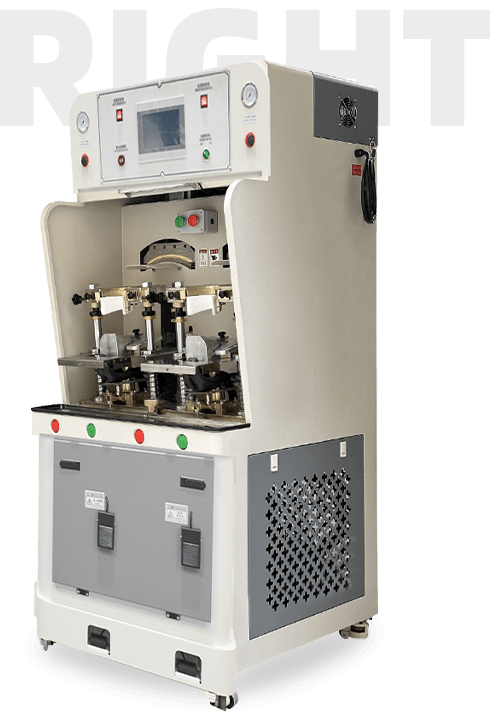

Using the original NGM brand compressor from Mexico, combined with the all-copper tube circulation cooling system, the mold surface temperature can be reduced to the set value (usually -10℃~5℃ adjustable) within 10 minutes, and the coolant reaches the key parts of the mold directly to ensure cooling uniformity. The air-cooled design does not require an external water source, is energy-saving, environmentally friendly and easy to maintain.

Molding Machine

Molding Machine ---

Comparison

alternating hot-cold precise molding eliminates

material stress; smooth and aesthetically

superior toe cap.

surface uneven; requires manual rework.

in one step; reduces operation time by 30% and

labor cost by 20%.

steps; time-consuming and low efficiency.

footprint; modular mold change; adaptable

to various last sizes.

change cumbersome.

2.Complicated to adjust; new workers find it difficult, requires long training?

3.Higher failure rate, frequent downtime, increased repair costs?

4.Single-zone heating wastes energy, low utilization efficiency?

5.Limited flexibility, hard to meet diverse shoe styles and quality standards?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

various men's, women's and children's shoes. It can also be

used for shaping the toe caps of hot melt adhesive welted shoes,

mark shoes and work shoes.