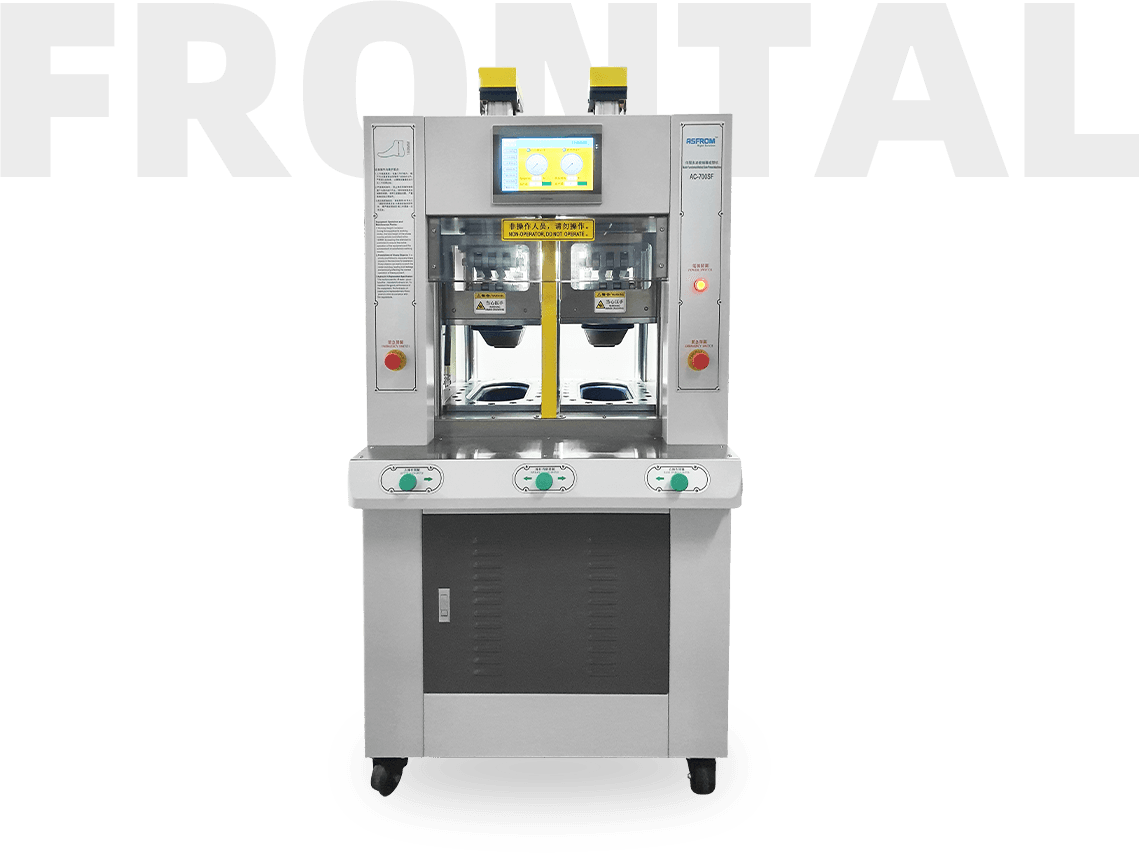

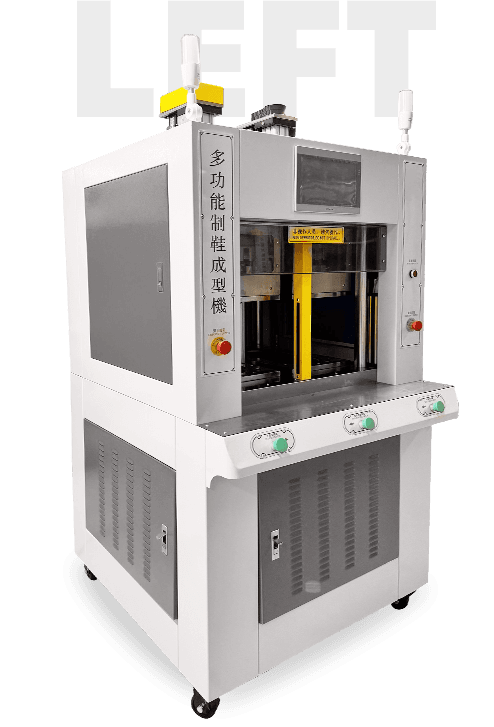

Non Molded Bottom Machine

(1) The pressure output is stable, and the pressure can be adjusted according to the different pressure requirements of shoe type. The pressure is far higher than that of conventional wall-type sole pressing machines, up to 30kg/cm². The advantages of non molded sole pressing machines can be more evident in shoe types with complex soles;

(2) Energy saving, one machine can complete the double sole pressing process, reducing the cost of shoemaking with multiple machines and multiple processes;

(3) Regardless of size, regardless of left or right foot, and does not require the production of traditional wall-type pressing molds, saving mold costs and mold change time;

Comparison

up to 30kg/cm²

hard to adjust

all-round pressing, no mold required

sole pressing in one machine

machines and processes required

2.Higher energy consumption, frequent maintenance?

3.Limited material compatibility, may damage soft soles?

4.Traditional process, lower output, depends on skilled operators?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

to achieve seamless bonding between the upper and outsole.

Suitable for running, basketball, and outdoor shoes, it efficiently

handles outsole assembly and bonding to ensure

high-quality finished products.