CUSTOMIZABLE MOLDS

what we do…

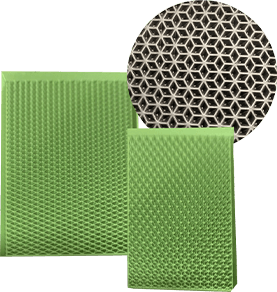

EVA and Rubber sheet mould

1. Save manpower and energy. 2. It can be produced continuously and automatically. 3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubber materials after mixing into it without material accumulation and residual material. 4. Good cooling efficiency, high cooling efficiency of the rubber compound. 5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenance and long machine life.

what we do…

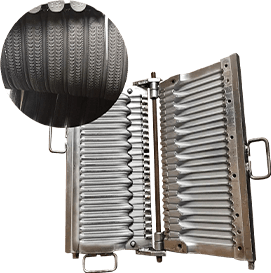

PVC strap mould

1. Save manpower and energy. 2. It can be produced continuously and automatically. 3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubber materials after mixing into it without material accumulation and residual material. 4. Good cooling efficiency, high cooling efficiency of the rubber compound. 5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenance and long machine life.

what we do…

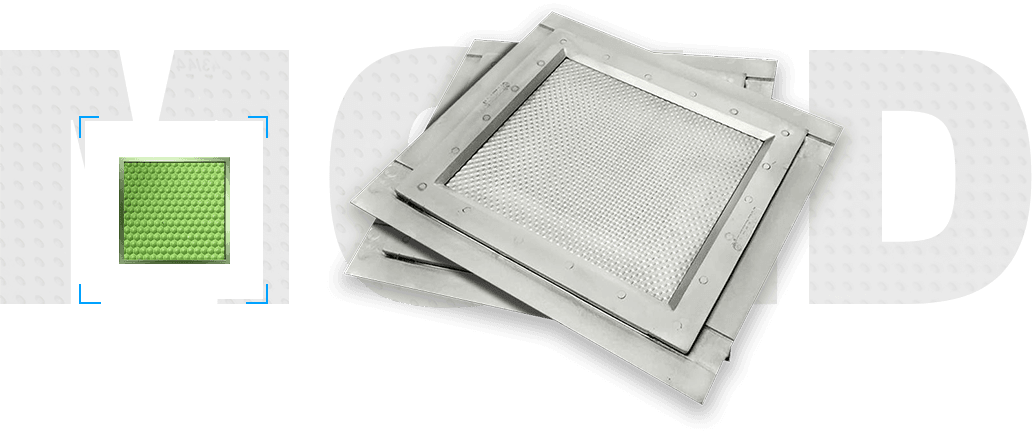

Sport shoes upper 3D molding mould

1. Save manpower and energy. 2. It can be produced continuously and automatically. 3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubber materials after mixing into it without material accumulation and residual material. 4. Good cooling efficiency, high cooling efficiency of the rubber compound. 5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenance and long machine life.

what we do…

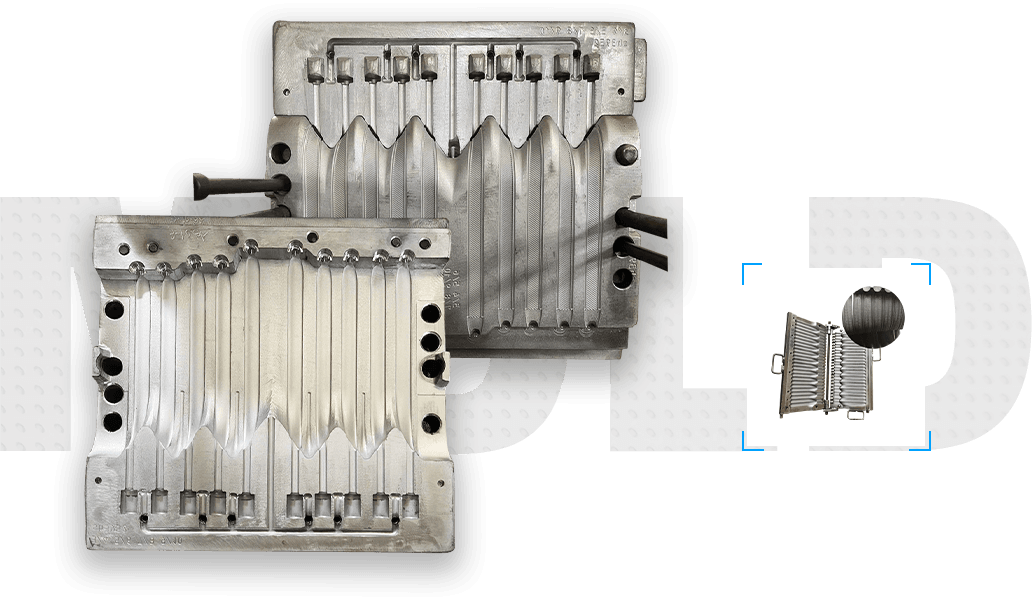

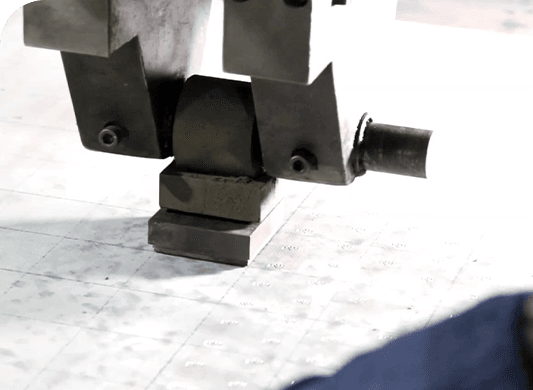

Insole embossing mould

1. Save manpower and energy. 2. It can be produced continuously and automatically. 3. The uniquely designed conical screw and extruding chamber can twist the whole batch of rubber materials after mixing into it without material accumulation and residual material. 4. Good cooling efficiency, high cooling efficiency of the rubber compound. 5. The feed inlet is wide and convenient for feeding, convenient material cleaning, simple maintenance and long machine life.

Contact me to customize the molds you need.

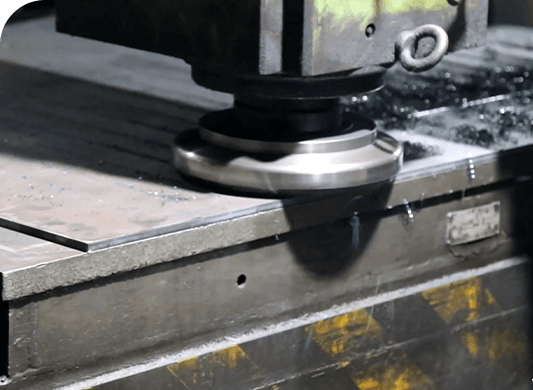

High manufacturing precision

Custom molds must meet stringent precision requirements, typically with tolerances at the micrometer level, to ensure the dimensional accuracy of molded products.

Complex Geometry

Custom mold cavities/cores often feature intricate curved surfaces or irregular structures, requiring high- precision machining techniques (such as EDM and CNC machining) to achieve complex shapes.

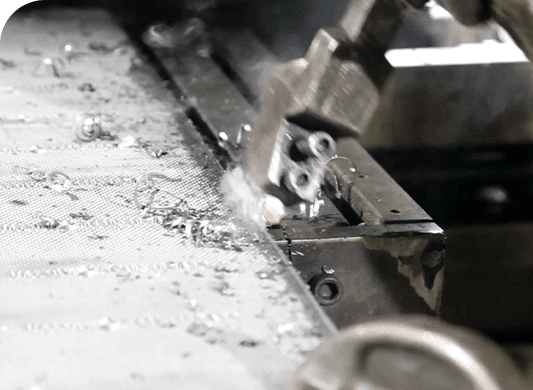

High Material Performance Requirements

Custom molds require the use of high-temperature resistant, wear-resistant, and high-hardness materials (such as tool steel and cemented carbide), with enhanced properties achieved through heat treatment.

Customized Production

Custom molds are typically used for single-piece or small-batch production, requiring flexible process adjustments to meet specific requirements. This approach involves longer production cycles and higher costs.

High Precision and Low Surface Roughness

The mold surface must exhibit low roughness to ensure molding quality; simultaneously, high precision must be maintained to prevent dimensional deviations in the product.

High Service Life Requirements

Custom molds must possess high durability to reduce repetitive production costs. For example, flow molds can be reused 200–500 times.