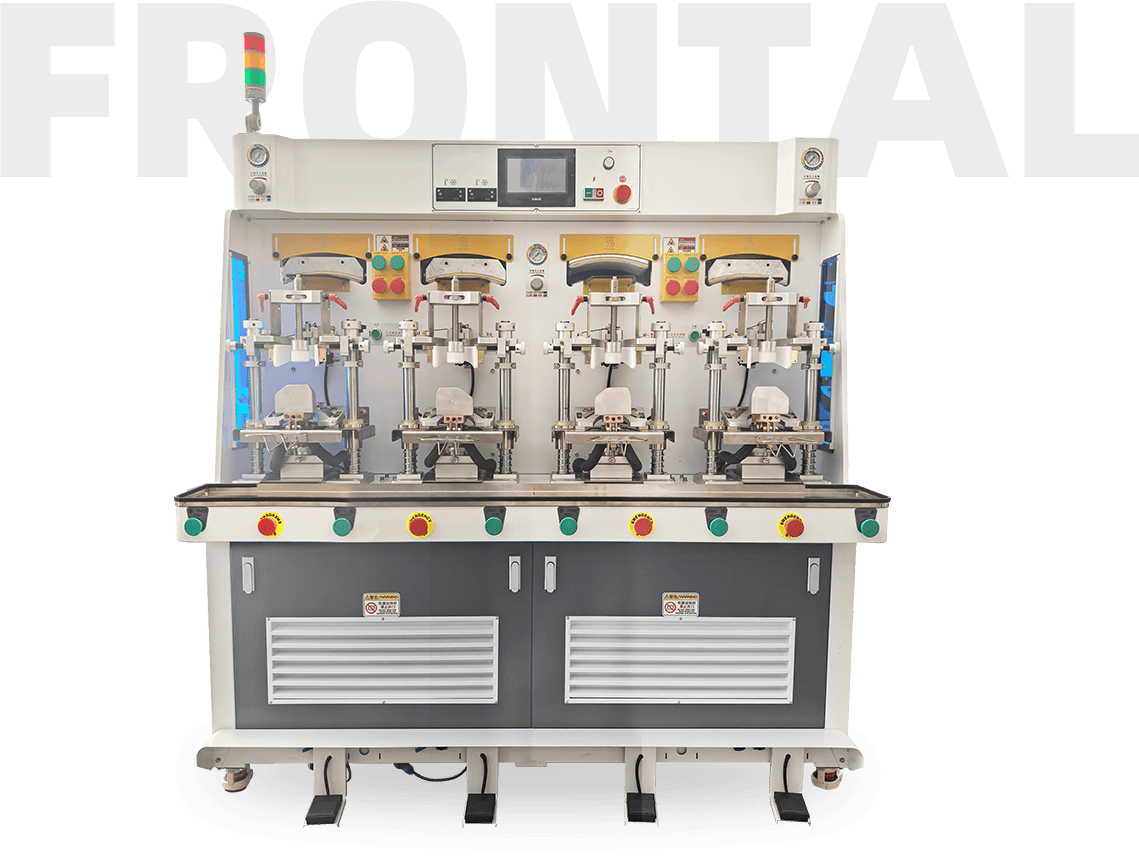

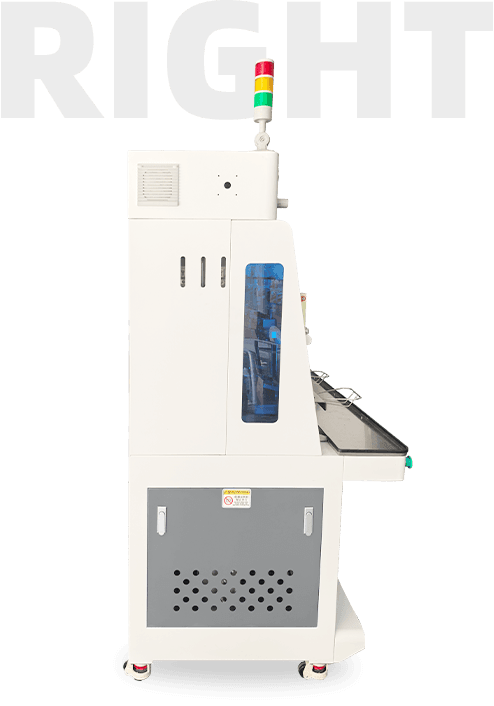

(For 4 Colds & 4 Hots)

(For 4 Colds & 4 Hots) ---

Comparison

machine, reaching 120°C in just 15 minutes with a

stable fluctuation of only ±2–5°C, suitable for

various materials.

distribution, and poor adaptability to different materials.

to 15°C in 5 minutes, ensuring uniform and

stable shaping.

leading to unstable shaping and deformation.

ensuring an ideal toe arc and accurate shaping;

easy to disassemble and maintain.

difficult maintenance, often failing to achieve

precise shaping.

2.Manual controls, less precise, requiring more operator experience?

3.Flat operating table, less ergonomic, causing higher fatigue during long operations?

4.Ordinary molds with low precision, time-consuming replacement,

poor fit, and inconsistent shaping results?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

casual shoes, leather shoes, California shoes and various shoes.