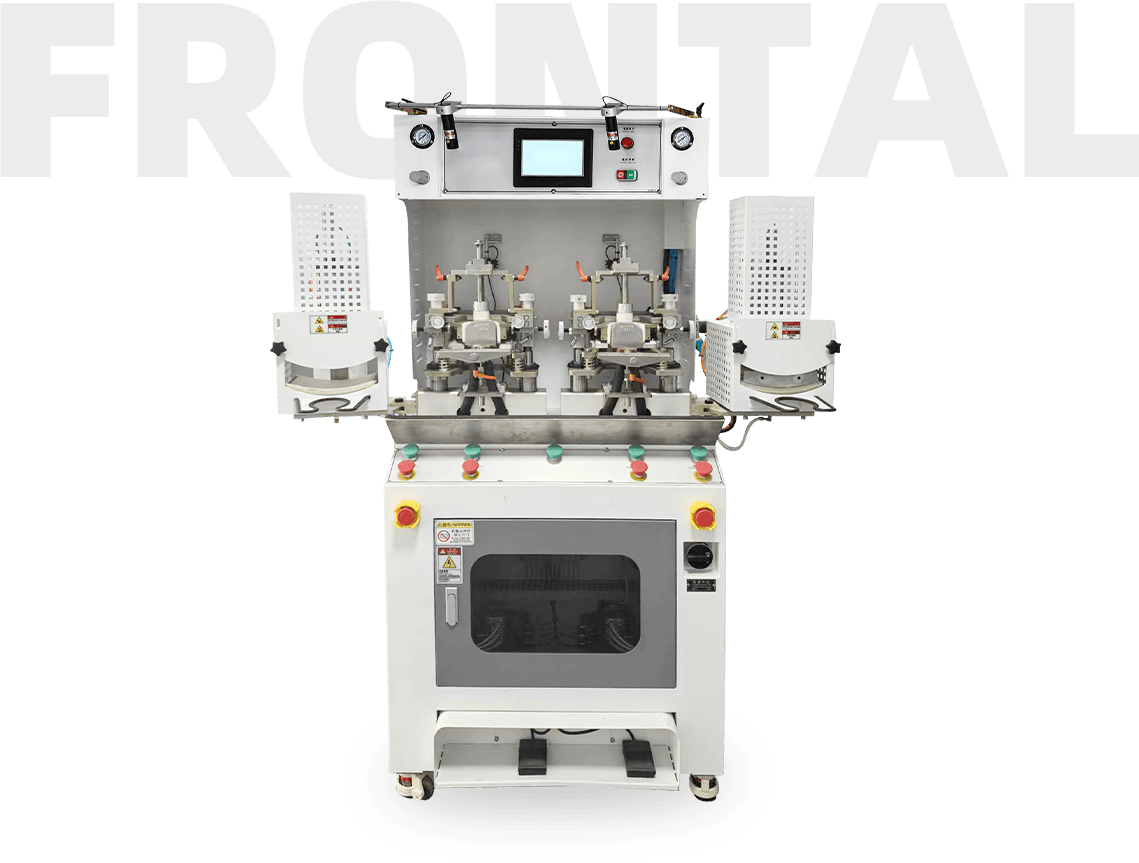

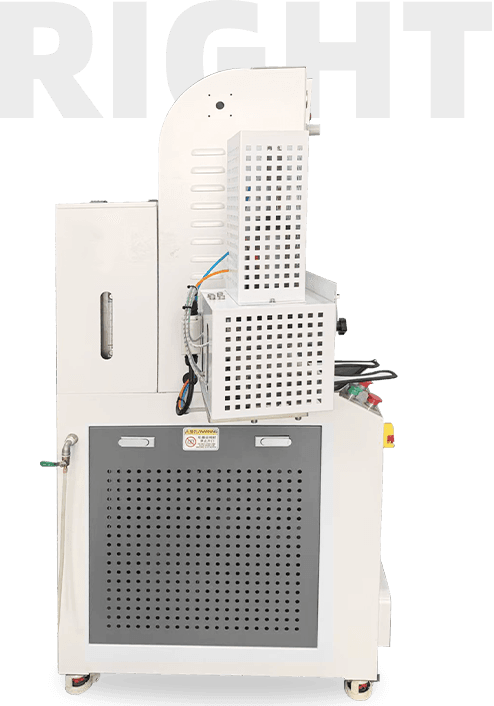

(For 2 Colds & 2 Hots)

(For 2 Colds & 2 Hots) ---

Comparison

temperature fluctuation 2–5°C

larger temperature fluctuation

uniform and stable

valgus/outward shoes

hard to shape outward shoes

2.Limited shoe types, mostly single type?

3.Poor temperature control, risk of overheating or underheating?

4.Fixed molds, limited heat softening or cooling effect?

4.Single hot or cold, slower shaping, lower precision, more labor?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

casual shoes, leather shoes, California shoes,valgus shoes and various shoes.