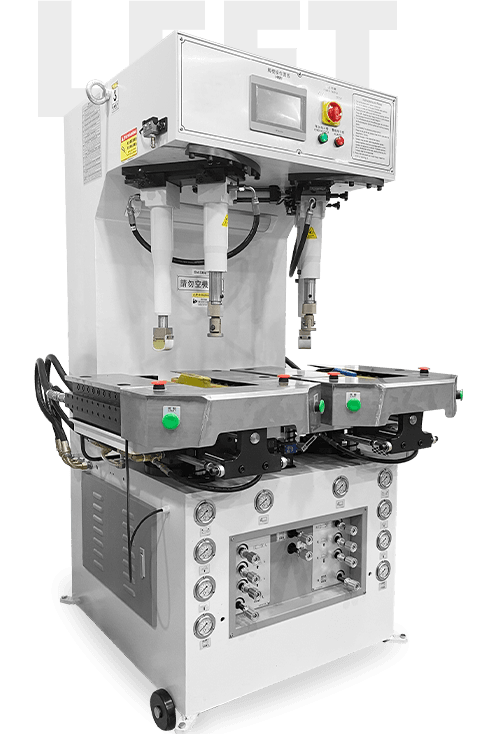

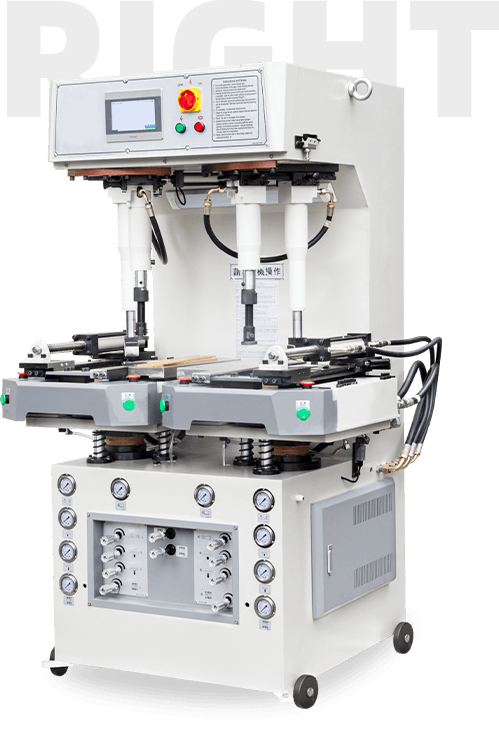

Two-stage pressurization mode: provides two modes: forming pressurization and post-forming pressurization. It can be flexibly selected according to material characteristics to avoid damage to the material and ensure stable quality;

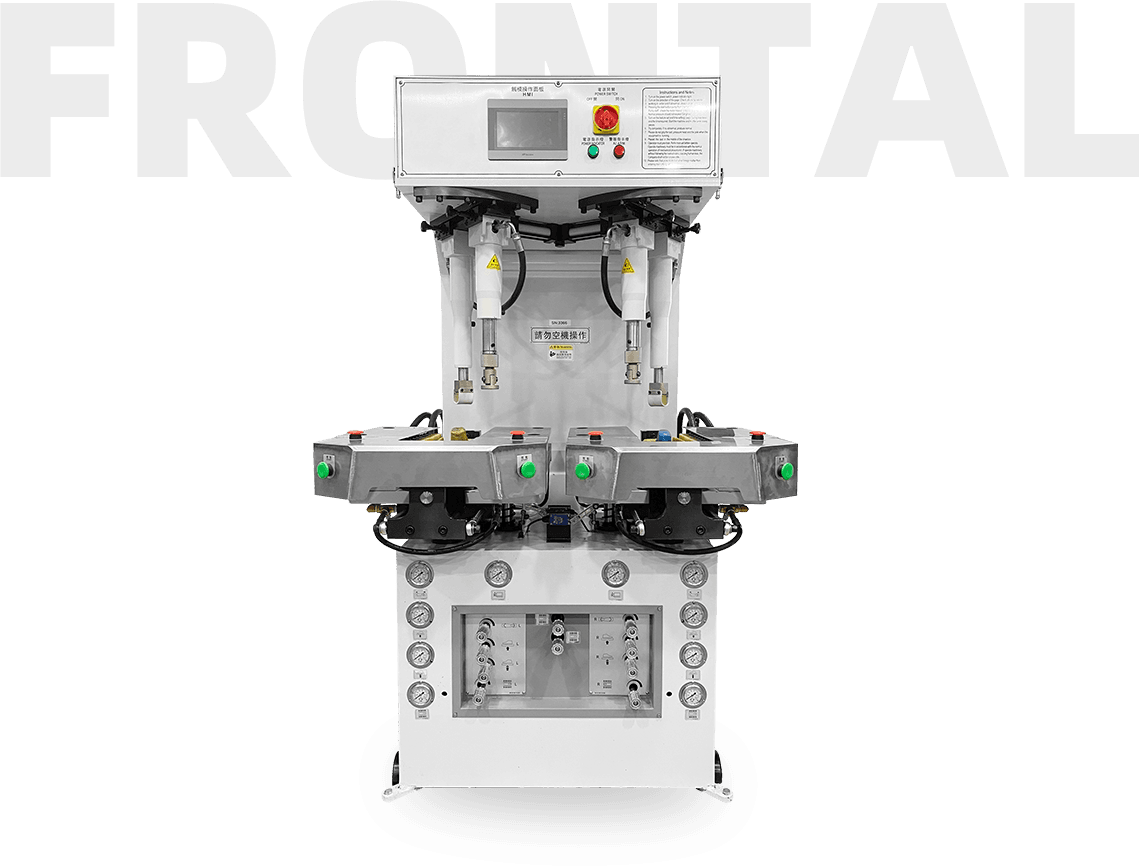

Hydraulic positioning technology: precise positioning through the hydraulic system, simplified operation process, and achieved firm bonding between the sole and the upper.

Patented steel ball sole mechanism: Based on the principle of steel ball fluidity, it ensures uniform pressure distribution during pressing, significantly improving the fit between the sole and the upper;

Rotating pressure rod mechanism: convenient operation, supports quick placement of shoe parts, and greatly improves production efficiency;

Bead-type balanced pressure: ensures uniform force during pressing of the outsole, enhances the bonding strength, and facilitates the removal of finished products.

Comparison

pressure, rotating rod for easy operation,

bead-type balanced pressure

manual adjustment required

switching; manual continuous operation with

automatic run

dependent on skilled operators

product removal

removal

2.Simple structure but prone to wear, frequent maintenance needed?

3.Limited material compatibility, may damage softer materials?

4. Higher energy consumption, lower efficiency?

5.Usually standalone, hard to expand?

Discover the power of smart lasting automation—stable, efficient, and easy to use.