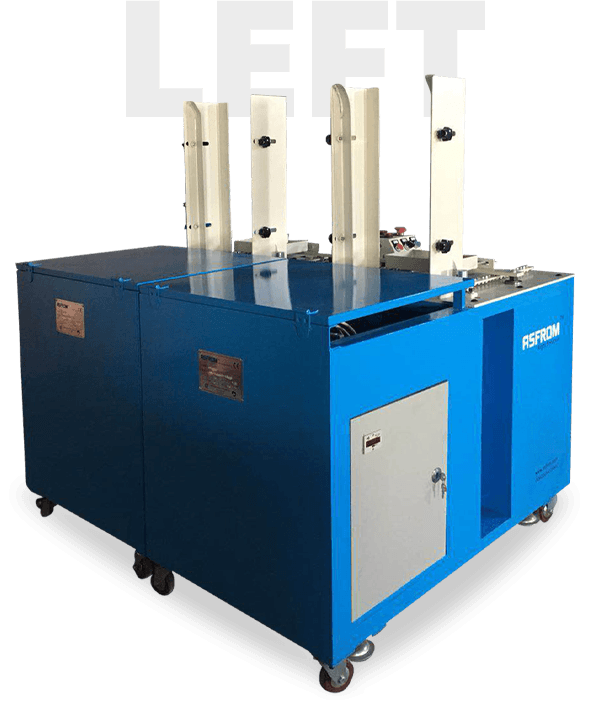

2.High Output – Capable of producing 300–600 pairs/hour, greatly enhancing production efficiency.

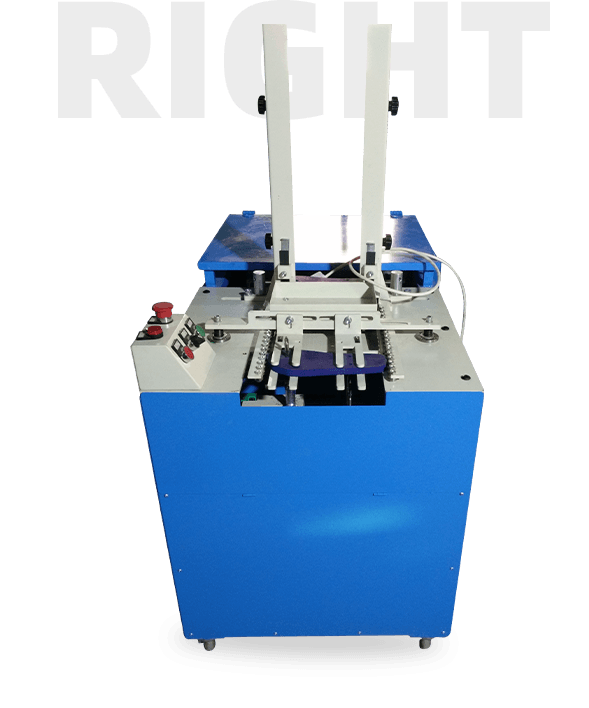

3.Precision Positioning – Ensures straps are aligned accurately, reducing defect rates.

4.Labor-Saving Design – Minimal manual work required, lowering labor costs.

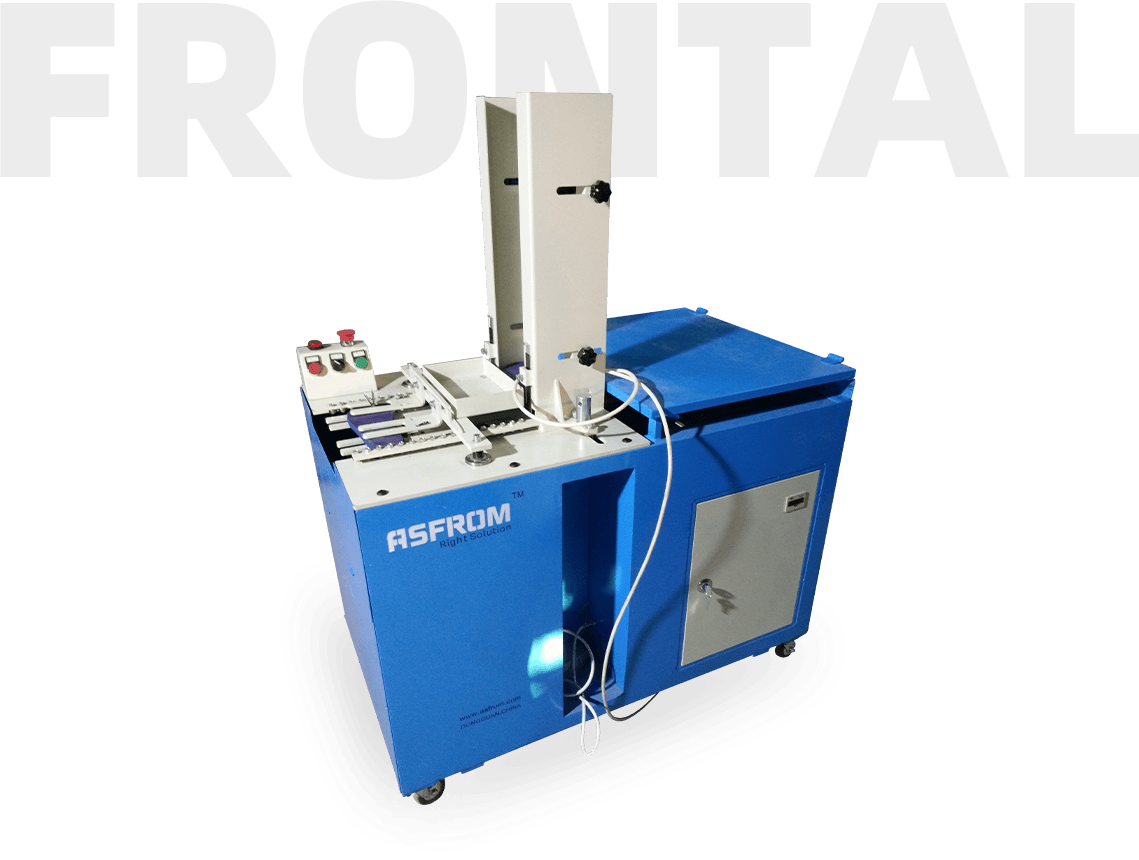

5.Durable and Low Maintenance – Robust build with reliable electric components for long service life.

Comparison

high output with stable quality.

inconsistent results.

saving labor.

and higher costs

alignment and consistent results.

strap positions.

2.Manual machines wear faster and require more service?

3.Manual strap insertion with slow speed and inconsistent results?

4.Multiple workers needed, causing fatigue and higher costs?

Discover the power of smart lasting automation—stable, efficient, and easy to use.

making it ideal for mass production of flip-flops and similar footwear.